A

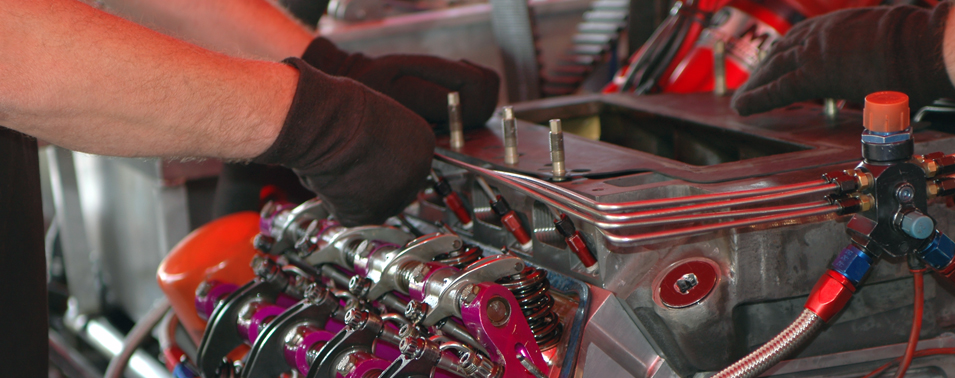

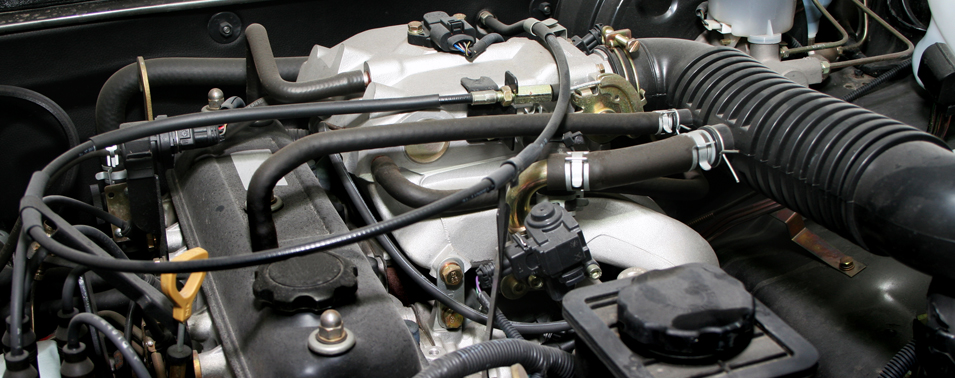

ENGINE REPAIR WORKSHOP can rotate at very high speeds. That’s why a

ENGINE REPAIR WORKSHOP must be perfectly balanced and fine-tuned to transform the maximum linear power of the motor into its rotary equivalent without generating damaging torsions or vibrations. A repaired

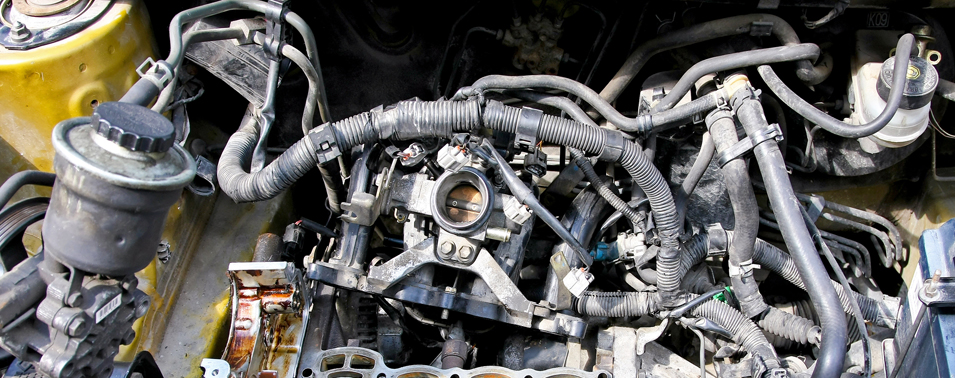

ENGINE REPAIR WORKSHOP, just like a brand new ENGINE REPAIR WORKSHOP must possess an effective damper at its opposite end to minimize torsion vibrations often caused along the

ENGINE REPAIR WORKSHOP length by cylinders that are farthest from the output end that tend to act on the torsional elasticity of the metal. All these minute adjustments must be perfect to get a

ENGINE REPAIR WORKSHOP to act as it’s supposed to and behave as perfectly as any EOM ENGINE REPAIR WORKSHOP would.

ENGINE REPAIR WORKSHOP Montreal repair shop RMMOTEUR has all the necessary equipment to make a perfect

ENGINE REPAIR WORKSHOP repair on all motor types, old or new, car or truck, diesel or gas-powered.

Less

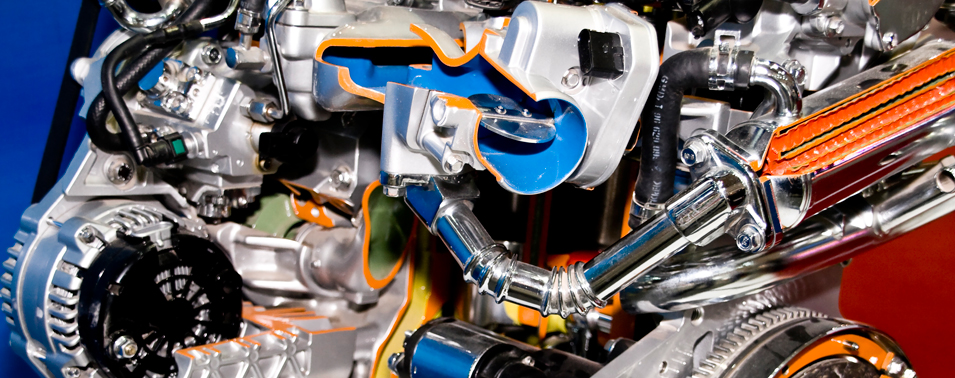

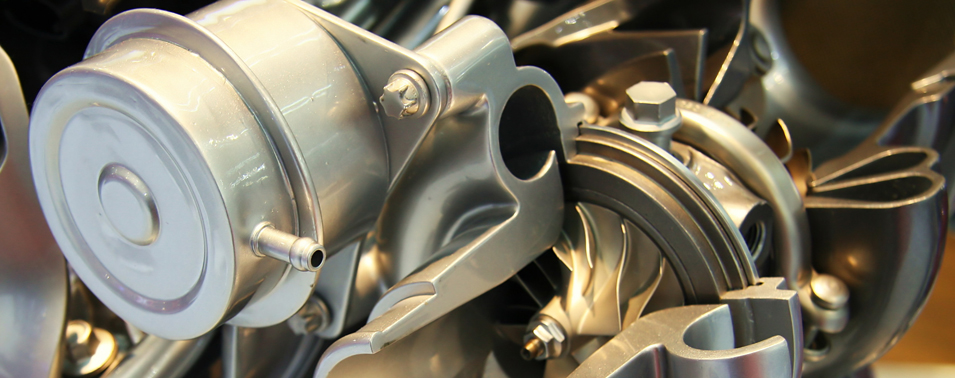

Each motor type, make and manufacturer designs each

ENGINE REPAIR WORKSHOP to optimize fuel efficiency, minimize heat production and coordinate all motor parts into a single, perfectly-integrated power delivery system. This perfect power unit must be considered as a whole when repairing a

ENGINE REPAIR WORKSHOP to get back to the original specifications the original

ENGINE REPAIR WORKSHOP maker determined. To do just that, every

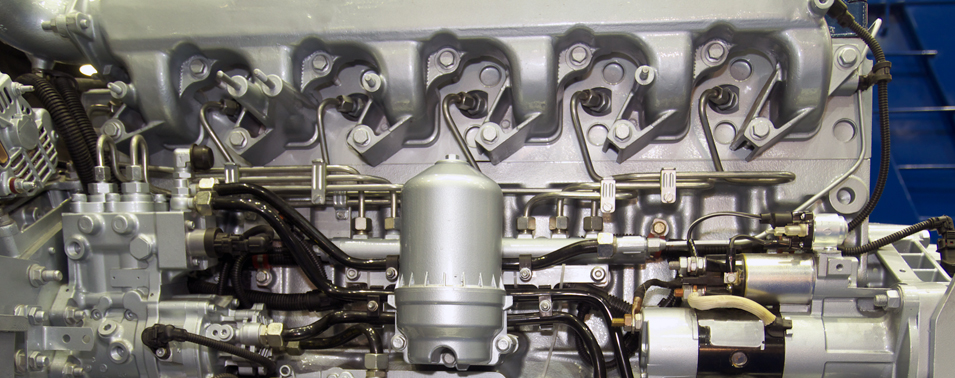

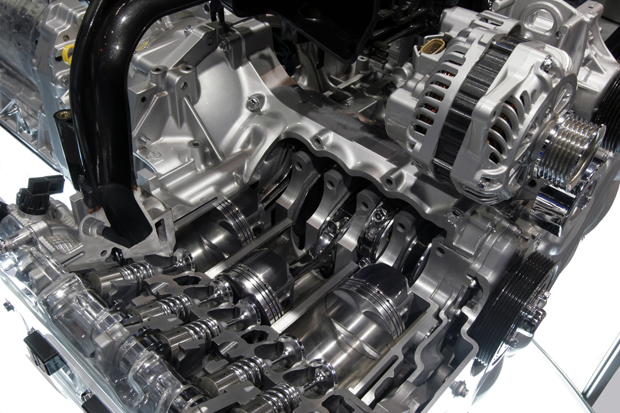

ENGINE REPAIR WORKSHOP repair, adjustment or refitting must recreate original parameters to recover the engine’s full capacity. Fixing a broken

ENGINE REPAIR WORKSHOP is much cheaper than buying a new motor, so making the right choice for

ENGINE REPAIR WORKSHOP repairs is paramount in not only fixing your broken

ENGINE REPAIR WORKSHOP, but in saving money as well.

Less